[ad_1]

One question entrepreneurs in the West ask themselves is whether they should find a manufacturer in China and outsource manufacturing to that low-cost region.

A large number of them are convinced that manufacturing in China will lower manufacturing costs and increase profits. However, some hold back because of doubts about whether China can manufacture products that meet their standards of quality. But there are a lot of searches for “manufacturing China” and similar queries on Google already, so clearly there are people looking into it.

Times Have Changed

Admittedly, there is a background to the origin of such doubts. However, it is 2019 now and there is no reason to be apprehensive about quality control in China. In this piece, we will tackle two points:

- Why you should set aside any doubts about the quality of manufacturing in China and begin importing from China

- How to find a manufacturer in China

1. Why You Should Set Aside Any Doubts You Have About the Quality of Manufacturing in China

Over the last 20 years or so, Chinese factories have made a fortune by manufacturing products that sell for low prices across the world.

You may remember a time when almost every souvenir you picked up while traveling—that Eiffel tower key chain in Paris, the leaning tower of Pisa fridge magnet in Italy, a replica of one of NASA’s shuttles at the Kennedy Space Center at Cape Canaveral, USA—showed a “Made in China” tag.

Ditto with the contents of dollar stores across the world, and the world’s entire supply of Christmas decorations, from tinsel to Santa hats to Christmas tree ornaments and even Christmas trees themselves.

There’s a Problem with Cheap Goods

The problem with

cheap goods, however, is that they tend not to last very long.

Therefore, because of the profusion of cheap, mass-produced goods that were “Made in China,” the brand became associated with low-quality goods.

This perception gained traction not only because of poor quality-control processes in factories in China but also because of the common perception in the West that “cheap” equals “poor quality.” However, the latter perception is not necessarily true.

Fast-Forward to 2019

Today, China has upped its manufacturing game. For example, it now manufactures high-end smartphones, laptops and other electronics, highly specialized aircraft components, drones, and other high-tech gear. In short, it has now gained a reputation of being able to manufacture high-quality goods at a competitive price.

There are two main reasons for this:

- Its own burgeoning and aspirational middle class—a huge consumer market—has become more discerning and more quality conscious. In the process, they have begun to seek good quality, safe products. This is the case whether they’re purchasing electronics, home décor, apparel, or toys.

- The Chinese government’s desire to improve the perception of the “Made in China” brand. In a 2017 article on how China planned to focus on improving the quality of its products and services, Xinhua, the official press agency of the Chinese government, said: “With an insufficient supply of high-end products and services, great efforts will be required to improve quality, according to the plan released by the Communist Party of China Central Committee and the State Council. The focus of the plan is on improving the quality of services and products, especially farm produce, food, medicine, consumer goods, and equipment.”

Additionally, China is now capable of manufacturing quality goods that are also competitively priced. Though the cost of raw materials in China has admittedly increased over the years—as it has elsewhere in the world—its labor costs are still competitive. That’s chiefly because of the huge pool of labor in China and the extensive infrastructure its government has set up for exports.

This is why China

is still the best place for business owners or entrepreneurs who are looking to

outsource some or all of their manufacturing needs.

If you are

convinced by this argument, we now get to the second point:

2. How to Find a Manufacturer in China

Finding a reliable manufacturer in China might seem a formidable task for business owners who are attempting to import from China for the first time. However, manufacturing in China is really not rocket science.

Here’s how to find a manufacturer in China:

Look on the World Wide Web for a Manufacturer in China

You need to give your initial search at least a month. Many people start out with a search on Google or Bing. However, you will save yourself time if you go directly to the several B2B websites such as Alibaba that help manufacturers in China to connect with buyers all across the world.

RELATED ARTICLE: THIS 3-STEP B2B MARKETING PLAN WILL BRING YOU MORE SALES

Depending on what you are looking for, check whether the suppliers thrown up by the Internet are middlemen or manufacturers.

That’s because buying directly from a manufacturer lowers costs, since middlemen such as traders take a cut that will reduce your profit margin.

Also, it is advisable to buy from a manufacturer directly if you want a product that your company has developed. This is also true if you need components that are difficult to get off the shelf easily.

Additionally, remember that some of the smaller manufacturers may not be visible on these sites for various reasons. For example, they might not have the SEO expertise necessary to get picked up by Internet search engines.

Visit Trade Fairs to Seek out a Manufacturer in China

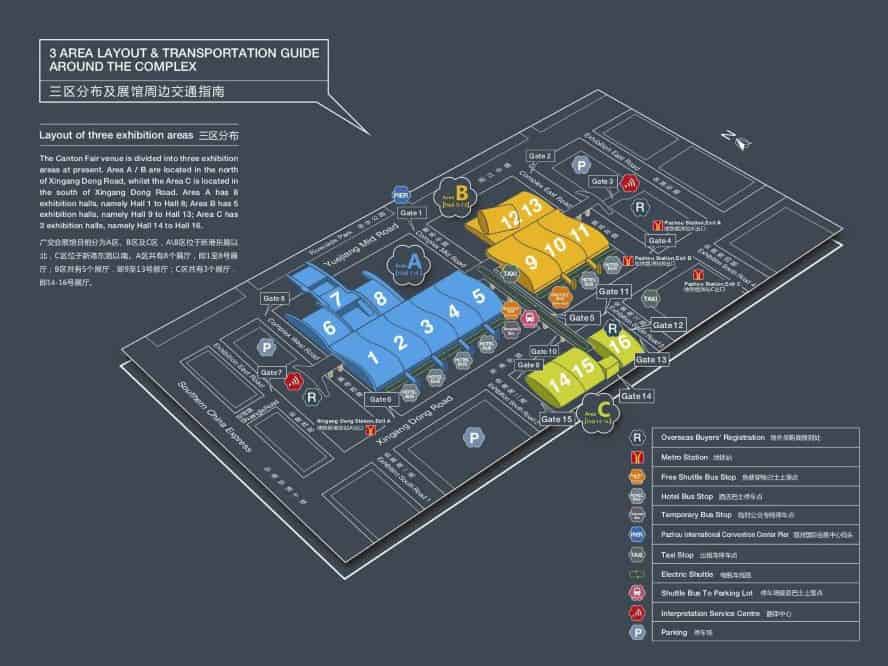

Visiting trade fairs in China and your home country will also give you some leads. China holds several such fairs through the year. For instance, the Canton Fair, held twice a year, in April and October, in Guangdong, is one of the biggest. It is so big that it is held in two or three phases each time.

The participants in this fair come from several industries: electronics and household electrical appliances, lighting equipment, vehicles and spare parts, machinery, hardware and tools, consumer goods, gifts, home decorations, and medical devices and health products. Plus, many more industries are represented.

Check out Other Big Trade Fairs, Too

Another big fair in China is the Yiwu commodities fair in Yiwu, Zhejiang. Yiwu also has a permanent trade market where buyers get good wholesale deals. You will find toys, sporting and recreation goods, office supplies, jewelry and accessories, household consumables, gifts and handicrafts, consumer electronics, apparel and clothing, hardware, stationery, and many other manufacturers at Yiwu.

Notably, the annual China International Hardware Show Shanghai has become the second largest exhibition in the hardware industry in the world. At this fair, buyers flock to buy tools, security systems, locks, and other hardware.

Several business owners from across the world visit these fairs to find suppliers, network with members of the industry, and even get new ideas for their businesses.

You Might Also Find Trade Fairs in Your Own Country That Feature Manufacturers in China

You could also see if your home country holds trade fairs that have exhibitors of the product you are interested in. For instance, in the US, the annual National Hardware Show, held in Las Vegas, usually has a number of manufacturers from China, as well as manufacturers from other countries.

Fall Back on Your Industry Network

You could find a reliable supplier in China through your industry network. This will include online and offline groups or your industry trade association. Also, sometimes word-of-mouth recommendations can be helpful and save you a lot of time. Why reinvent the wheel, right?

Rely on Sourcing Agents to Find a Manufacturer in China

Often, smaller business owners who already have their hands full running their companies prefer not to handle the China sourcing themselves. Instead, they conduct their business in China via an agent who acts as their representative throughout the manufacturing process.

Of course, such agents charge a fee to supervise everything for you. For example, they will find you a supplier, verify the supplier’s credentials, examine your designs, get a sample made, suggest improvements, supervise production, and handle problems that crop up on the factory floor. Finally, they will conduct the pre-shipment quality check and handle the shipping.

However, if you decide not to opt for a sourcing agent, you’ll need to shortlist a few suppliers, then contact them. When you do, list your key requirements and request a quotation.

These requirements should include:

- The type of manufacturing, such as die casting, metal stamping, or plastic injection molds.

- The raw material required and what the product is used for.

- Whether you have a design or need help with a design and whether you have a mold or you need one to be made.

- Your minimum order quantity or MOQ.

- How often you are likely to place the order in a year.

- Their prices for samples, a trial run, and mass production.

- How long it will take them to make your order.

- Their payment terms.

- Whether they have manufactured for a Western company before.

Shortlist Suppliers That Respond

Once the suppliers you have contacted respond, you must shortlist them. Besides taking into account the price quoted (obviously), also assess them on the quality of their response. For instance, did they answer all your questions? And did they respond within a reasonable time?

Their English doesn’t need to be impeccable. But you must get the sense that they understand what your requirements are. This is crucial, especially if you intend to have a long-term business relationship with them. Remember that you are dealing with people in a different country, which operates in a different time zone, and where a different language is spoken.

Once you have finalized a few suppliers, ask them to make a sample before making your final decision on the basis of the quality of the sample.

A Final Word

Do remember,

however, that before you sign any agreements you must either verify the

credentials of the factory yourself or through a third party. You could ask the

factory for their business licenses and other certifications to verify whether

they indeed are legitimate and have the capacity and capability to manufacture

your product. As mentioned above, a good sourcing agent also does this for you.

[ad_2]

Source link

Leave a Reply